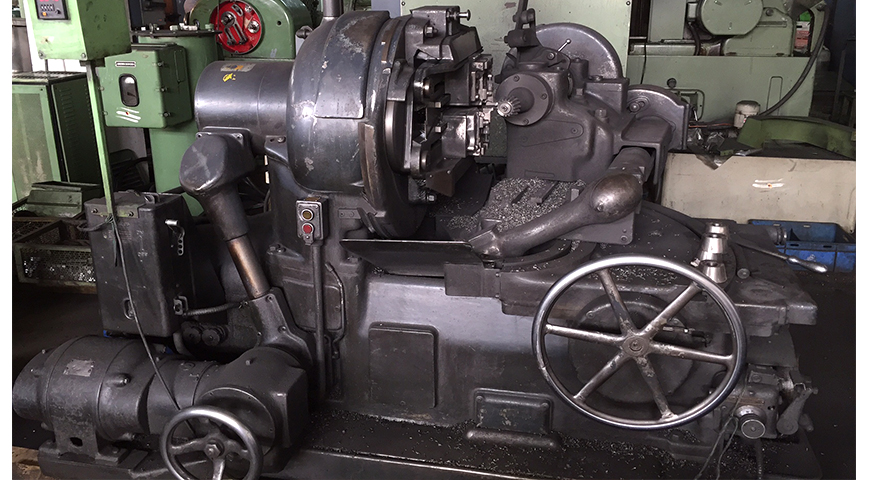

The incorporation of Computer Numerical Control (CNC) for Hobbing, Reishauer Gear grinding, Gleason Bevel Gear Generator, Mitsubishi Wire Cut EDM and Lindner worm grinding has paved way for greater Accuracy and Precision leading to production of reliable and long lasting Quality products.